Understanding prized for their combination : Durable, Versatile, and Practical

Diamond plate sheets, also known as tread plates, checker plates, or floor plates, are a type of metal stock with a regular pattern of raised diamonds or lines on one side. These sheets are prized for their combination of strength, functionality, and aesthetic appeal, making them ideal for a wide range of industrial, commercial, and residential applications.

What Are Diamond Plate Sheets?

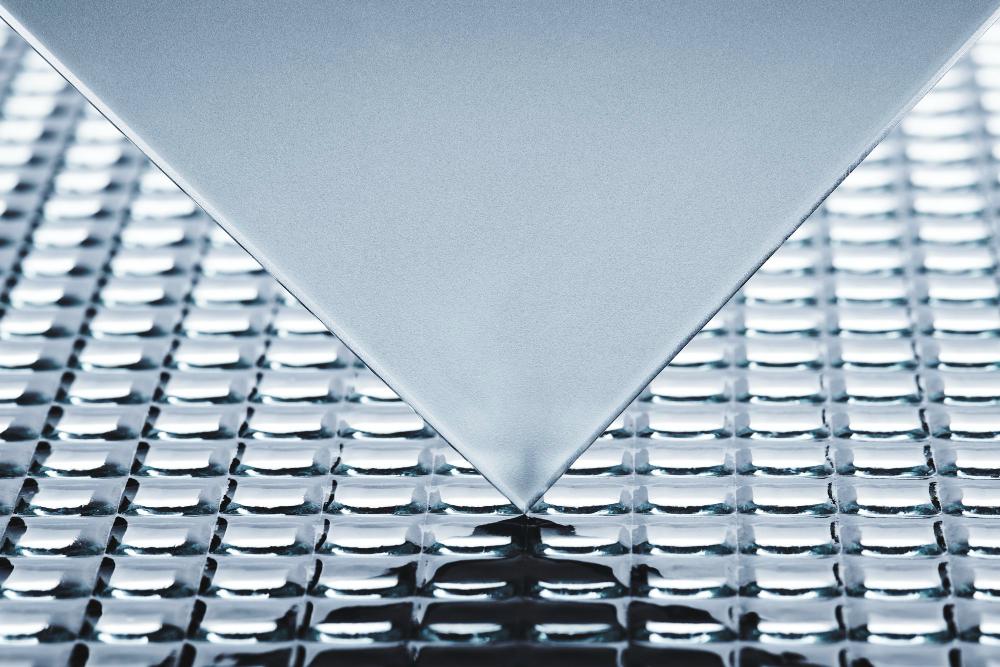

Diamond plate sheets are typically made from aluminum, steel, or stainless steel. They are characterized by a distinct textured surface on one side, which enhances grip and reduces the risk of slipping. The reverse side is usually smooth.

These sheets are rolled or stamped to form the raised pattern, giving them both form and function. While they are primarily used for their anti-slip properties, they also add a rugged, industrial aesthetic wherever they are installed.

Common Materials Used

1. Aluminum Diamond Plate

Aluminum is the most popular choice for diamond plate sheets due to its lightweight properties and corrosion resistance. It’s often used in applications where weight is a concern—like in truck toolboxes, trailers, and loading ramps.

2. Steel Diamond Plate

Steel is stronger and heavier than aluminum, making it ideal for environments that demand superior strength and impact resistance, such as factory floors or heavy equipment surfaces.

3. Stainless Steel Diamond Plate

Stainless steel diamond plates are corrosion-resistant, durable, and perfect for environments exposed to moisture or chemicals, such as kitchens, labs, or clean rooms.

Key Benefits of Diamond Plate Sheets

1. Slip Resistance

The most recognized feature of diamond plate sheets is their anti-slip surface. The raised diamond pattern creates traction, which significantly reduces the chance of slipping—especially in wet or oily conditions.

2. Durability

Whether made from aluminum or steel, diamond plate sheets are built to last. They can withstand heavy loads, resist impact damage, and perform well under extreme conditions.

3. Easy Maintenance

Diamond plate sheets are relatively easy to clean. Dirt and grime can be wiped away or washed off, especially for aluminum and stainless steel versions that resist rust and corrosion.

4. Visual Appeal

The industrial look of diamond plate adds a modern, rugged style to both functional and decorative applications. It’s often used in garages, man caves, or architectural elements for its bold appearance.

Common Uses of Diamond Plate Sheets

1. Industrial Flooring

Manufacturing facilities and warehouses use diamond plate sheets for flooring and stair treads due to their non-slip and heavy-duty nature.

2. Vehicle Modifications

From truck bed liners and trailer walls to motorcycle footrests and ATV ramps, diamond plate is a go-to material in the automotive and transportation industries.

3. Toolboxes and Storage Units

Diamond plate is commonly used for toolboxes because of its strength, light weight (in aluminum form), and eye-catching finish.

4. Wall and Surface Protection

In environments where walls are exposed to wear and tear—like loading docks or corridors—diamond plate sheets act as both protection and decoration.

5. Kitchen and Commercial Use

Stainless steel versions are popular in commercial kitchens, food trucks, and industrial applications due to their hygiene, durability, and easy-to-clean surface.

Installation Tips

Installing diamond plate sheets depends on the intended use. For flooring, adhesive and fasteners may be used. When applied to walls, screws or rivets often provide secure attachment. It's essential to ensure the surface is clean and flat before installation to maximize adherence and performance.

Choosing the Right Diamond Plate Sheet

When selecting a diamond plate sheet, consider:

-

Material: Aluminum for light-duty and portability; steel or stainless steel for strength and corrosion resistance.

-

Thickness: Thicker sheets offer more durability but may be harder to work with.

-

Finish: Polished finishes enhance appearance, while matte finishes reduce glare.

-

Environment: Exposure to moisture, chemicals, or weight loads will influence your choice of material and thickness.

Final Thoughts

Diamond plate sheets combine functionality and visual appeal, making them a favorite in industries ranging from automotive to architecture. Whether you're upgrading a work truck, reinforcing a shop floor, or adding industrial flair to an interior design, these sheets offer a reliable and durable solution.

Their enduring popularity stems from their practical benefits and the tough, modern look they bring to any space. With proper selection and installation, diamond plate sheets can offer years of performance in even the most demanding environments.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness