The Role of Aerospace Production Tooling in Modern Aircraft Manufacturing

In modern aircraft manufacturing, precision and efficiency are everything. Every component must meet strict quality standards, and production processes must minimize errors and delays. This is where Aerospace Production Tooling comes into play. Tooling plays a critical role in shaping, assembling, and verifying components, ensuring that aircraft meet stringent safety, performance, and regulatory requirements.

This article explores the key role of aerospace production tooling, its types, benefits, and how it contributes to modern aircraft manufacturing.

What is Aerospace Production Tooling?

Aerospace production tooling refers to specialized equipment and tools used to manufacture, assemble, and inspect aircraft components. These tools are designed for high precision and durability to support the production of complex parts like fuselages, wings, engine components, and landing gear systems.

Tooling includes jigs, fixtures, molds, gauges, and automated machinery that ensure consistency, accuracy, and repeatability in production processes.

Why Tooling is Critical in Aircraft Manufacturing

Aircraft manufacturing is highly complex, requiring millions of parts to fit together seamlessly. Tooling is critical for several reasons:

1. Ensures Precision and Accuracy

Even minor deviations in aircraft components can lead to safety risks or operational inefficiencies. Aerospace tooling provides the precision required to produce parts that meet exact specifications.

2. Enhances Production Efficiency

Custom tooling streamlines production by guiding assembly, reducing manual errors, and speeding up repetitive processes. This improves throughput while maintaining quality standards.

3. Supports Regulatory Compliance

Aerospace production is heavily regulated. Tooling ensures components are manufactured and inspected according to strict aviation standards, helping manufacturers comply with FAA, EASA, and other regulatory bodies.

Types of Aerospace Production Tooling

Tooling in aerospace manufacturing comes in various forms, each designed for specific functions:

1. Jigs

Jigs are devices that guide tools during machining or assembly. They ensure consistent positioning and orientation of parts, improving repeatability and accuracy.

2. Fixtures

Fixtures hold workpieces securely in place during manufacturing or assembly. Unlike jigs, which guide tools, fixtures focus on stabilizing the component to maintain exact positioning.

3. Molds

Molds are used to shape composite or metal components. In aerospace, molds are critical for producing complex structures like wing skins and fuselage sections.

4. Gauges

Gauges measure dimensions and tolerances during production. They are essential for inspection and quality control, verifying that components meet precise specifications.

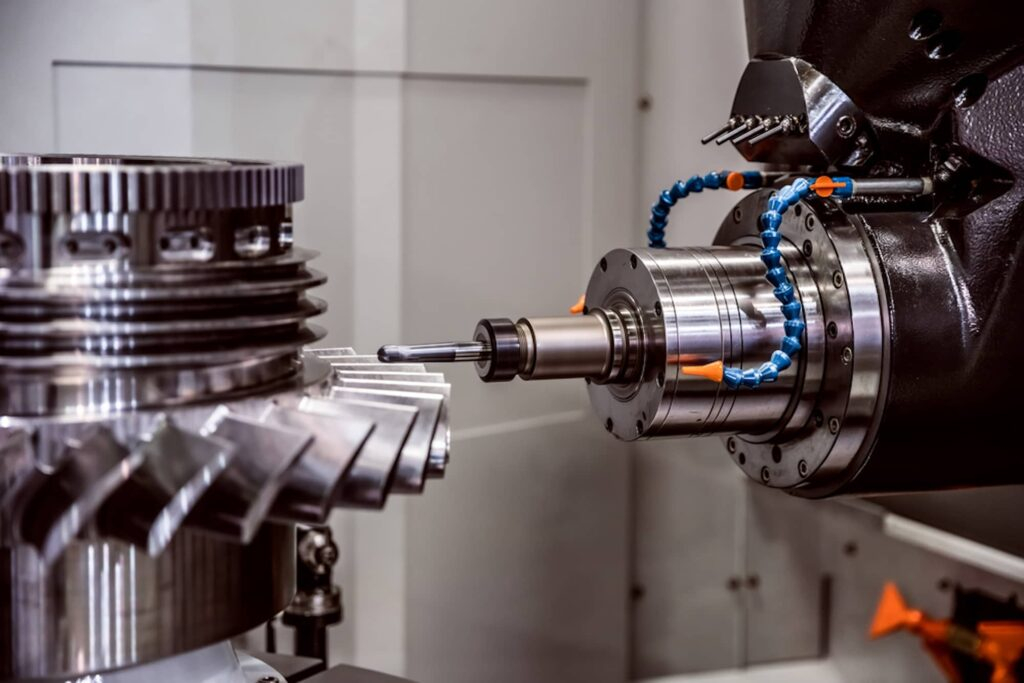

5. Automated Tooling

Computer-controlled machines, robotic arms, and CNC equipment fall under automated tooling. These tools increase speed, consistency, and precision in large-scale aircraft production.

The Role of Tooling in Assembly Processes

Tooling is not only important in part fabrication but also in aircraft assembly. Here’s how it contributes:

1. Aligning Components

Fixtures and assembly jigs ensure fuselage sections, wings, and other structural components are aligned accurately during assembly.

2. Reducing Human Error

By guiding technicians and holding parts in place, tooling minimizes errors and ensures each assembly step is completed correctly.

3. Enhancing Safety

Proper tooling reduces the need for excessive manual handling, lowering the risk of injuries to assembly personnel and ensuring the integrity of components.

Tooling for Composite Materials

Modern aircraft increasingly use composite materials for lighter, stronger, and more efficient components. Aerospace production tooling for composites is specialized:

1. Layup Tooling

Layup tooling supports composite sheet placement, ensuring fibers are aligned properly for optimal strength and durability.

2. Curing Tooling

Curing tooling maintains the correct pressure and temperature during the curing process to achieve high-quality composite components.

3. Precision Cutting Tooling

Specialized cutting tools are used to shape composite parts without damaging the material or compromising strength.

How Tooling Impacts Quality Control

Tooling plays a central role in quality control across all stages of aircraft manufacturing:

1. Consistency Across Production

Jigs, fixtures, and gauges ensure that every part produced meets the same specifications, eliminating variability in large production runs.

2. Dimensional Accuracy

Aerospace tooling allows precise measurement and alignment, ensuring components meet strict dimensional tolerances.

3. Inspection and Verification

Tooling such as coordinate measuring machines (CMM) and custom gauges assist in inspecting parts for defects, warping, or deviation from specifications.

Economic Benefits of Aerospace Tooling

Investing in high-quality tooling delivers significant economic advantages to aerospace manufacturers:

1. Reduced Production Costs

Tooling streamlines processes, reduces waste, and minimizes errors, lowering overall production costs.

2. Faster Time-to-Market

With precise tooling, manufacturers can produce parts faster and more efficiently, accelerating aircraft delivery schedules.

3. Long-Term ROI

Although initial tooling costs may be high, the improved efficiency, reduced errors, and consistent quality deliver a strong return on investment over time.

Challenges in Aerospace Tooling

Despite its advantages, aerospace tooling comes with challenges:

1. High Initial Investment

Developing custom tooling for aircraft components is expensive due to precision requirements and material costs.

2. Maintenance and Upkeep

Tooling must be regularly maintained to prevent wear and ensure continued accuracy, adding ongoing costs to production.

3. Technological Complexity

Advanced tooling for composites or automated systems requires skilled operators and sophisticated software for optimal performance.

Future Trends in Aerospace Production Tooling

The aerospace industry continues to innovate, and tooling evolves with new technologies:

1. Automation and Robotics

Automation increases precision, reduces errors, and accelerates production. Robotic systems can perform complex machining and assembly tasks with minimal human intervention.

2. Additive Manufacturing (3D Printing)

3D printing is increasingly used for producing custom tooling and lightweight components, offering faster turnaround and more flexibility in design.

3. Smart Tooling and IoT Integration

IoT-enabled tooling can monitor performance, detect wear, and provide real-time data for predictive maintenance, improving efficiency and reducing downtime.

Choosing the Right Aerospace Production Tooling Provider

Selecting a reliable tooling provider is critical for quality and efficiency. When evaluating suppliers, consider the following:

1. Experience and Expertise

Choose a provider with a proven track record in aerospace production tooling. Look for experience in both metal and composite tooling, as well as complex assembly solutions.

2. Customization Capabilities

Your tooling provider should be able to create bespoke solutions tailored to your aircraft design, production processes, and tolerances.

3. Quality Assurance

Ensure that the provider follows stringent quality control standards, provides accurate documentation, and complies with aerospace certifications and regulations.

A trusted supplier, such as Aerospace Production Tooling, can deliver tailored solutions to meet the unique challenges of modern aircraft manufacturing.

Conclusion: The Essential Role of Aerospace Production Tooling

Aerospace production tooling is the backbone of modern aircraft manufacturing. From precision machining and composite layup to assembly and inspection, tooling ensures accuracy, efficiency, and safety at every stage. Investing in high-quality tooling not only improves productivity but also enhances the quality and reliability of aircraft components.

For manufacturers aiming to stay competitive in today’s aviation market, partnering with experienced Aerospace Production Tooling providers ensures that aircraft are produced with precision, efficiency, and compliance, meeting the high standards demanded by the aerospace industry.

- الألعاب

- Religion

- Party

- Networking

- Music

- Literature

- Art

- Health

- Gardening

- Shopping

- Food

- Fitness

- Film

- Drinks

- Dance

- Crafts

- Causes

- Wellness

- Devotional Reflections

- Bible Study & Scripture Insights

- Prayer & Worship

- Christian Living

- Spiritual Growth & Discipleship

- Testimonies & Personal Journeys

- Christian Theology & Doctrine

- Church Calendar & Liturgical Seasons

- Christian Service & Mission

- Gardening

- Health

- الرئيسية

- Literature

- Networking

- أخرى